Products

- Home

- Application

- Mechanical Seals Top Entry

- Mechanical Seal GT1911A

Mechanical Seal GT1855A

2018-05-07

Mechanical Seal GT1910A

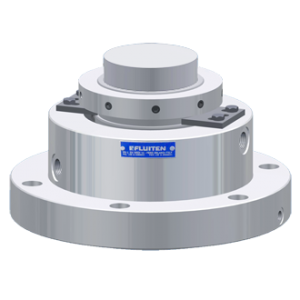

2018-05-07Mechanical Seal GT1911A

Double seals with gas flushing.

Latest generation gas lubricated double seal developed to safeguard the environment and eliminate process contamination.

The seal is designed with “Fluilift” non contacting face technology, and is pressurized with an inert gas that lubricates the faces and provides a gas barrier between process and atmosphere.

The seal incorporates laser etched grooves that maintain a controlled gap between the faces, even at low rotating speeds, eliminating friction, heat generation and process contamination.

Power consuption is also reduced. Designed using API 682 construction guidelines.

Features

- Seal rings designed using FEA to ensure correct flatness in all operating conditions.

- Flange designed to guarantee correct stationary ring alignment.

- Optional: sanitary gland to avoid product contamination and cooling jacket for high temperature applications.

- Retained stationary ring to prevent blow out during reverse pressure.

- Connection for gas flushing.

- Multiple springs for uniform face loading.

- Positioning device for easy, precise installation.

- Self-alignment drive collar.

- Three robust drive lugs that can tolerate run-out and vibration.

| DIAMETER | 35 – 200 (mm) |

|---|---|

| SPEED | 0 – 10 (m/sec) |

| PRESSURE | 0 – 10 (bar g) |

| TEMPERATURE | -20 – 200 (°C) |

Be the first to review “Mechanical Seal GT1911A” Cancel reply

Reviews

There are no reviews yet.